Introducing Our New Online Shop!

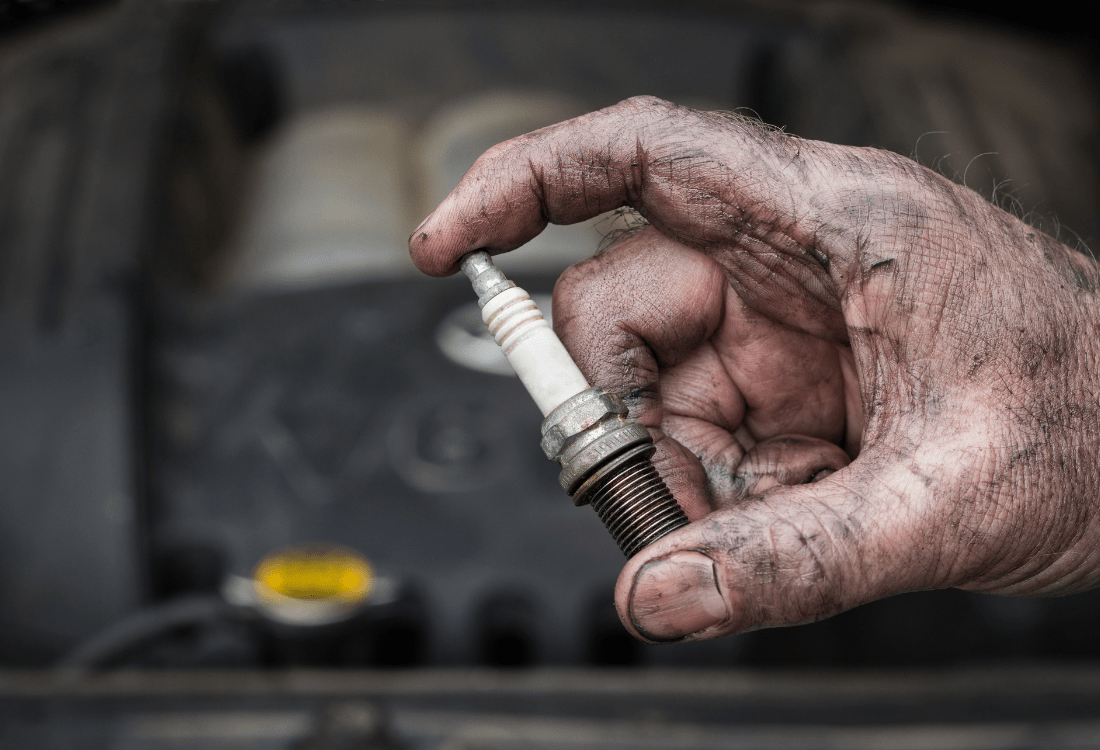

We are excited to announce the launch of our new RM Walsh online shop where you can quickly and easily purchase industrial engine ignition products such as spark plugs, HT leads, ignition accessories, and more, all in one place!

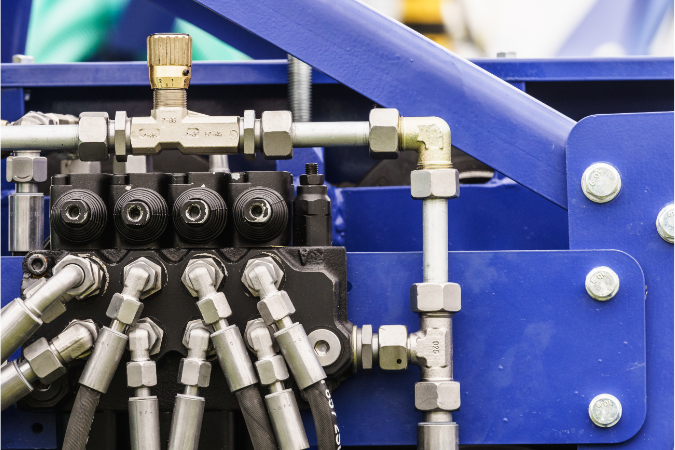

Replacement HT Leads For Jenbacher 400/600 Series Industrial Gas Engines

At R & M Walsh, we understand how important it is to keep your Jenbacher gas engines operating in full working order.

We also recognise that only the highest quality replacement parts will ensure your plant’s productivity and availability, reducing unexpected downtime, improving efficiency, and decreasing your operating costs.

- Page 1 of 4

- Next page

Apply for an Account

Apply for an Account Log In

Log In 0Basket

0Basket Checkout

Checkout

01782 983376

01782 983376 info@rmwalshltd.co.uk

info@rmwalshltd.co.uk