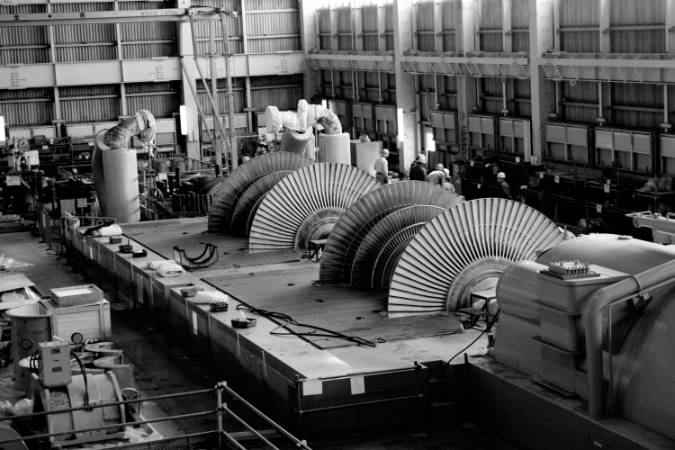

A combined heat and power (CHP) plant relies on the smooth operation of its engine to generate electricity and heat for industrial, commercial, or residential buildings. Therefore, regular maintenance is essential to extend the lifespan of your CHP plant and avoid costly breakdowns. Fortunately, there are several maintenance tasks you can carry out yourself in house as part of your proactive maintenance approach.

Daily Checks And Inspections

To ensure the daily smooth running of your CHP plant, we recommend implementing a daily inspection routine. During each inspection, you’ll need to check for oil leaks, water leaks, loose screws, and panels, as well as looking out for signs of excess heat, unusually noisy operation, or unexpected vibrations. If you experience any of these problems, they could indicate an impending critical fault. Catching such indications early can be crucial in avoiding significant damage to the plant.

Weekly Checks

On a weekly or fortnightly basis (depending on usage), inspect your CHP plant's spark plugs for faults and replace them if necessary. You should also clean and check the spark plug gaps. When refitting, ensure you replace the spark plug gasket or crush washer correctly. These small, often-overlooked components can have major performance impacts on your plant when they are not correctly maintained.

Monthly And Quarterly Maintenance (Usage Dependent)

For monthly or quarterly maintenance (check with your manufacturer for their recommendations based on operating hours), sample your engine oil for contamination, remove, clean or replace your air and oil filters, and clean your HT leads (replace if necessary).

Ensuring that the engine oil is clean and free from contaminants is especially crucial to the longevity of the plant engine. Similarly, ensuring that the air and oil filters are cleaned and replaced at appropriate intervals will help to prevent unforeseen engine problems and downtime. Proper maintenance of your HT leads will minimise the risk of power loss and electrical faults in your CHP plant engine.

Continuity And Resistance Testing

The final in-house maintenance task you shouldn’t ignore is to periodically run a continuity and resistance test through your HT lead. This should be done every six weeks or so, depending on usage. Continuity tests are essential whenever there is an issue with the HT leads, and resistance testing will help establish the integrity of the HT leads and determine whether or not they need to be replaced.

The Right Maintenance Schedule To Safeguard Your Assets

Maintenance is very important for CHP plants and it is crucial that you take a proactive approach to maintenance, both through third-party professional servicing and routine maintenance you can carry out yourself. Paying attention to routine maintenance and inspections will help you avoid a lot of the common problems that lead to breakdowns, and reduce the lifetime cost of professional servicing and repairs.

At R&M Walsh Ltd., we provide a variety of high-quality spark plugs and components for CHP plants. To find out more or to place an order, please get in touch today.

Image Source: Canva

Apply for an Account

Apply for an Account Log In

Log In 0Basket

0Basket Checkout

Checkout

01782 983376

01782 983376 info@rmwalshltd.co.uk

info@rmwalshltd.co.uk