Ignition leads are a vital part of any gas-powered industrial engine. They transfer the electrical charge sent for the ignition coil to the spark plug, igniting the gas and air mixture. Without keeping them in good shape, your industrial engines may stall, misfire, malfunction, or not run at all.

It’s important to keep your ignition leads in the best condition possible to prevent this from happening. Here’s our three-step guide to keeping your ignition leads in the best possible condition.

1. Correct Installation

Prevention is better than cure. The first step to long-lasting spark plug ignition leads is to make sure that they’re correctly installed in your engine. Get professional help to do this if you don’t have the expertise to install leads in-house.

Make sure that the lead ends are connected correctly to the ignition coil. This can be in the form of a bolt which is tightened or a simpler push-pull fitment. Failure to do so can lead to a loss of energy transferred to the spark plug. Avoid overlapping and protect from any heat created from manifold/exhaust as this can lead to a loss of voltage and eventual part failure.

Check the OEM specifications to make sure your leads are installed as the manufacturer intended. Make sure that your leads are installed on a cooled, deactivated engine. Working on a gas-powered engine that is still warm can lead to your newly installed machine parts warping or developing faults.

2. Regular Cleaning

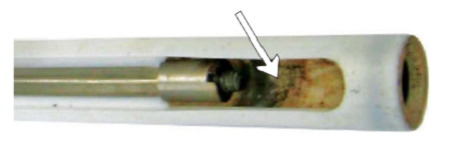

One of the main causes of HT lead failure is contamination. Particulates (such as oil, dirt, carbon, or metal flakes) from the engines surrounding which can build up over time, result in decreased performance and damage to internal components. Excess dirt and oil can also be spread around by the engineer.

Like any other component, your leads and their connecting points should be kept clean of contaminants to ensure a long working lifespan. Once the engine has cooled down, make sure that when inspecting your HT leads, coils, and spark plugs they are kept clear of oil, dust, or any other contaminants.

You can use cloths, scrapers, and specially adapted spark plug cleaners for maintenance. However, abrasive industrial cleaning chemicals should be avoided. These may end up doing more damage to the leads than they prevent.

3. Regular Checks

Some build-up of particulates is unavoidable when using high-voltage, industrial-grade spark plugs. Nevertheless, you can limit carbonisation and oxidisation by scheduling regular engine checks by trained engineers. As well as cleaning, they’ll be able to tell you which parts are at risk of wearing out. In some cases, there may be replacement seals boots and connections available to extend the life of your HT lead.

Ignition Leads From RM Walsh

If you’re looking for new ignition leads or need to replace worn-out ones, come to RM Walsh. We specialise in supplying gas engine parts to customers throughout the United Kingdom. Call or email us today for a free quote.

Apply for an Account

Apply for an Account Log In

Log In 0Basket

0Basket Checkout

Checkout

01782 983376

01782 983376 info@rmwalshltd.co.uk

info@rmwalshltd.co.uk